Food & Beverage

Food & Beverage market leaders and small private companies across the continent use the advantages of onsite power generation centered on Jenbacher gas engines. Such reliable onsite power solutions help to reduce operating costs, convert organic waste to energy, and as a result, help companies be more sustainable and competitive.

Our dedicated Jenbacher experts are available to provide personal consultation.

If you produce or process soft drinks, beer, dairy products, chocolate, flour products or something else, most likely, you use electricity and heat in production, and with a high degree of probability, you generate waste that can be converted into biogas.

Jenbacher produces innovative onsite power generation solutions for applications from 250 kW to 200 MW. Our experts are ready to consult you on how Jenbacher gas engines can help in your specific case, whether your waste can be converted into biogas, and what is required to do so. We help customers to calculate the loads, select necessary equipment, with flexible operations, and calculate economic models for your potential project.

Jenbacher Cogeneration or CHP (Combined Heat and Power) solutions are designed to generate both heat and power, especially for food and beverage applications, helping to decrease operational expenses and improve manufacturing processes.

How it works

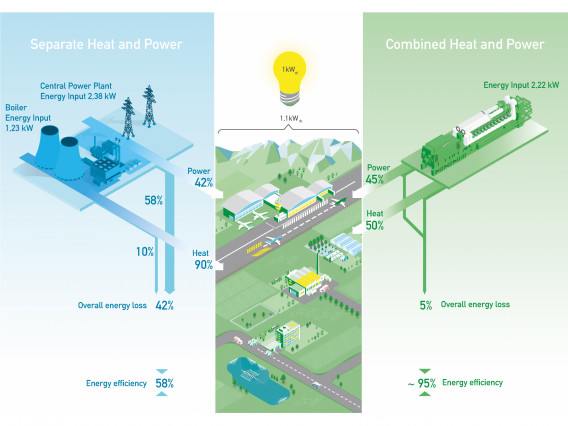

Simultaneous production of heat and power at the point of use is usually more efficient versus separate production at electrical power plants and boiler houses. Cogeneration solutions based on Jenbacher engines work with total efficiency up to 90% and more, maximizing benefits for your business.

Cogeneration process at a glance: in addition to efficient electricity production, Jenbacher CHP systems convert the waste heat created during an engine’s operation into useful hot water or steam, that can generate total CHP plant efficiencies of more than 90%. This efficient and economical method of energy conversion achieves primary energy savings of roughly 40% by using a gas engine cogeneration system instead of separate power and heat generation equipment. Transportation and distribution losses also are reduced or eliminated as the decentralized energy supply is deployed where it is needed.

*Based on IEA ’16 electricity production figures for EU-28 and EIA ‘17 average power plant heat rate references

Why Onsite Cogeneration?

Jenbacher CHP solutions are used by our food & beverage customers across the globe, powering applications in a wide variety of segments, for example – production of cold beverages, alcoholic drinks, chocolate, milk products, flour products, and many more.

Jenbacher onsite cogeneration solutions can help your company to achieve economic targets thanks to one or several of factors, such as:

- Decrease of energy – related operational expenses compared to centralized energy sources or;

- Launch or extend company operation due to access to new power generation in energy – deficit areas or;

- Minimize downtime, thanks to improved quality of the electricity supply in the regions with unstable grid infrastructure or;

- Convert waste produced by your operations into power or;

- Decrease your company’s carbon footprint, helping to meet your environmental commitments, and much more.

Tailor-made solutions for your operations:

The basic structure of Jenbacher CHP systems includes a gas engine/gas generator unit and heat exchangers that use waste heat. A wide range of heat sources—from gas engine cooling water and oil to an air/fuel gas mixture and exhaust gas—is configured to give each individual customer the greatest possible benefit.

The basic structure of Jenbacher CHP systems includes a gas engine/gas generator unit and heat exchangers that use waste heat. A wide range of heat sources—from gas engine cooling water and oil to an air/fuel gas mixture and exhaust gas—is configured to give each individual customer the greatest possible benefit.

Jenbacher CHP modules can be installed either inside buildings or packaged into ready–to-use containerized CHP solutions. Containerized cogeneration power plants allow our food and beverage customers to start using the benefits of onsite power generation quickly. Our cogeneration plant solutions deliver flexible power generation and a high degree of reliability and availability.

Jenbacher CHP modules can be installed either inside buildings or packaged into ready–to-use containerized CHP solutions. Containerized cogeneration power plants allow our food and beverage customers to start using the benefits of onsite power generation quickly. Our cogeneration plant solutions deliver flexible power generation and a high degree of reliability and availability.

Exhaust heat from the engine can be converted into hot water, steam, and other types of process heat. Jenbacher solutions can be efficiently integrated with your current energy equipment.

If needed, produced heat can be converted to cold with use of absorption chillers, which results in an efficient solution for generating air conditioning and/or refrigeration.

Moreover, a power plant’s exhaust gases can be used to produce clean CO2 for your operations (e.g. to add to your sparkling beverages).

As an option, cogeneration solutions can be supplemented with a peak boiler system for bridging peak heat demand periods. The connection of a heat storage medium makes it possible to increase system operating time and efficiency.

Jenbacher onsite CHP solution can work in baseload, mid-merit and peak shaving regimes, and you can modify these regimes depending on your needs.

Cogeneration power plant electrical switch and control systems distribute electricity and manage the engine, while hydraulic equipment ensures heat distribution. Generated power can be used by a facility, and excesses of electricity can be fed into the public power grid.

Jenbacher solutions efficiently work in both island mode and grid – parallel mode depending on your requirements.

Convert your operations organic waste to energy

Jenbacher works not only on natural gas, but on a wide variety of gases including biogas. In many cases, waste of your manufacturing could be fermented to produce biogas and this biogas can be used in our engines. In addition to efficient cogeneration using biogas, it also could help your company to meet environmental targets.

Our engines can work on a biogas – natural gas mix. Moreover, in many cases, with use of additional equipment, it is possible to switch periodically between biogas and natural gas.

Reach out to our experts, to know how Jenbacher solutions could help your business.

Features & Benefits

- Decrease of your company’s OPEX.

- Fast access to reliable source of power.

- Cogeneration systems generate both heat and power.

- INNIO’s cogeneration gas gensets are designed to maximize electrical and overall efficiency: yielding 48% electrical efficiency and combined heat and power efficiency up to 90%.

- Generally, 40% more energy is saved vs. separate power and heat generation equipment.

- Cogeneration reduces or eliminates transportation and distribution losses.

- Generated power is used by an individual facility or fed into a public power grid.

- Full power is achieved within 10 minutes.

- Thermal energy can be used to generate heating water and steam production, as well as for various types of process heat.

- Designs are lightweight, compact and modular.

- Efficient combined production of power, heat and cold (trigeneration), by integrating CHP solutions with absorption chillers.

- Production of clean CO2 for a company’s operational processes.

- Convert your waste into biogas and use it to fuel your power plant and to decrease your carbon footprint.

Microgrids Business Case Simulation:

Food & Beverage Industry

The food & beverage industry has specific energy demands for electricity and thermal energy. The following use case displays how a microgrid solution can help the industry reduce energy costs and add resiliency while achieving sustainability targets.

Experience our webinar: Learn about our CHP solutions

Jenbacher North American team invites you to review the recording of our recent webinar, to learn how Jenbacher can help you develop your power plant projects, including equipment design and performance, using hydrogen and much more! In the webinar, you will learn more about:

- Overview of an independent power plant and its components

- Jenbacher’s highly efficient type 6 genset

- Our hydrogen power generation solutions

- How proven equipment design improves performance

- Power generation solutions with quick delivery and easy installation

The information provided is relevant for the North American market. Please reach out to our experts to discuss your project.

Our experts are ready to help you

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher´s regional experts can advise you on which solution makes the most sense for you.

Get in touch for free consultation on the following:

- The benefits of onsite power generation solutions for your company

- Potential financial benefits using economic modeling

- Consultation on the technical side of your project – fuel types, feasibility studies, equipment and balance of plant selection, and more

- Regional incentive programs relevant to your business

- Options to deliver your project: purchasing, financing and leasing, engaging a service provider (ESCO, BOO etc.)

- How to meet emissions targets

Fill-in contact form, or send us an email contact.en@innio.com.

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.