Coal Mine Gas

Making coal mining safer and cleaner.

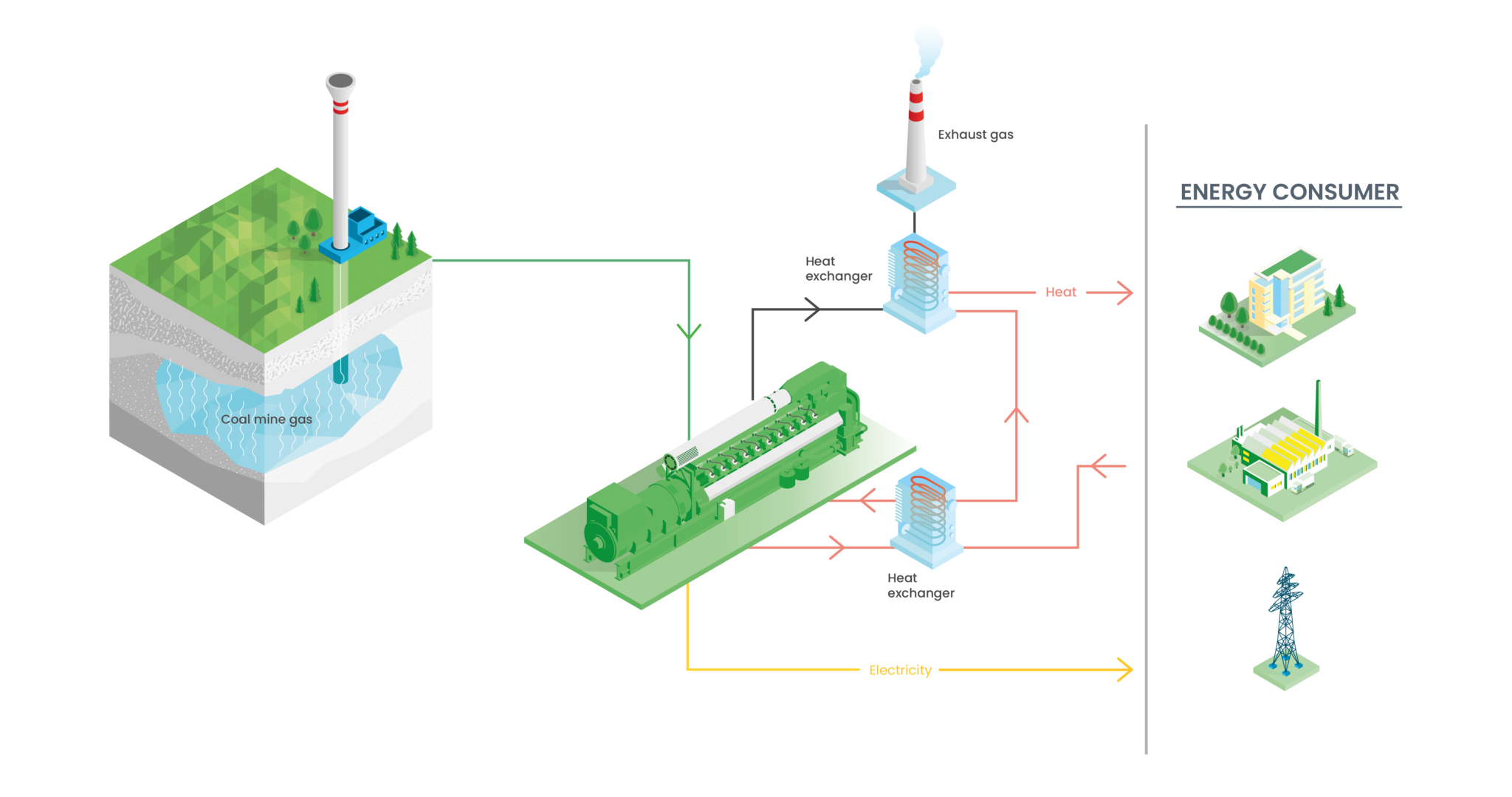

Mines often are located in remote regions where power from the grid is not reliable – if available at all. But with Jenbacher gas engines, mining operators can put hazardous coal mine gas to use, generating more than enough heat and power for their operations while also mitigating greenhouse emissions. Sometimes they can even sell excess energy to the grid.

Our dedicated Jenbacher experts are available to provide personal consultation.

Mine degasification

In many coal mines, the methane gas byproduct is vented to the atmosphere by exhaust fans as a greenhouse gas. Further degasification often is needed for worker safety, usually through the installation of various types of gas suction systems before, during, and also after coaling.

With Jenbacher gas engines, captured hazardous coal mine gas can be used to generate heat and power for safer, more efficient, and environmentally friendlier mining operations. Plus, excess heat and power can be routed to a district heating system and public utility grid for additional revenue.

Coal mine gas

Three different types of coal mine gas exist, and methods vary for the capture and use of each::

- Coal Bed Methane (CBM)

Also called Coal Seam Gas (CSG), Coal Bed Methane from unmined coal beds consists of more than 90% methane and can be harvested independently of coal mining in some locations. The gas composition is very stable, meaning that the gas can be fed either directly into a natural gas network or a gas engine. - Coal Mine Methane (CMM)

Coal Mine Methane, a methane/air mixture released during active coal mining, must be captured and vented for safety reasons. CMM typically has an oxygen content from 5% to 15% and a methane content from 25% to 60%. However, the methane/air proportion can change suddenly, thus complicating its use in gas engines. - Abandoned Mine Methane (AMM)

Even after coal mines are shut down, coal mine gas continues to be released. Although coal mine gas from abandoned mines typically contains no oxygen, it does contain a considerable amount of carbon dioxide (from 3% to 20%), and its composition changes slowly compared to CMM. The methane content ranges from 40% to 80%.

The INNIO solution for mining industry

Most larger underground hard coal mines contain CMM and AMM, both of which can be used effectively for power and heat generation with Jenbacher gas engines.

However, sudden changes in the composition of CMM from active mining put greater demands on the engine design.

INNIO has developed a special gas mixing and engine control system that allows the efficient use of this gas down to a methane content of only 25%. Additionally, Jenbacher gas engines are designed to operate on full load despite low gas pressure, high humidity, dust load, and altitude.

The electrical energy generated can be used in the coal mine to meet electricity requirements or fed into the public power grid. The thermal energy can be used for heating purposes on -site or fed into a district heating system.

Your benefits

- Enhance worker safety—with an installed or refurnished gas suction system

- Mitigate greenhouse gases—through alternative disposal of a problem gas while simultaneously harnessing it as an energy source

- Monetize carbon credits—with additional revenues from feed-in tariffs or through carbon credit projects, as applicable

- Increase revenue from power and heat—by feeding any surplus into the public grid and eventually supplying warm water or steam to the consumer

- Enjoy smooth, reliable operation—despite fluctuations in gas pressure and methane content

- Achieve excellent overall efficiency—as high as 90% in combined heat and power applications and up to 43.5% in power generation alone

- Get fast load capability—from zero to 100% load in 10 minutes

- Install quickly, even in tight spaces—with a compact and modular design that meets low footprint and dynamic weight-per-kW requirements

Our experts are ready to help you

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher´s regional experts can advise you on which solution makes the most sense for you.

Get in touch for free consultation on the following:

- The benefits of onsite power generation solutions for your company

- Potential financial benefits using economic modeling

- Consultation on the technical side of your project – fuel types, feasibility studies, equipment and balance of plant selection, and more

- Regional incentive programs relevant to your business

- Options to deliver your project: purchasing, financing and leasing, engaging a service provider (ESCO, BOO etc.)

- How to meet emissions targets

Fill-in contact form, or send us an email contact.en@innio.com.

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.