myplant Performance

MORE PERFORMANCE THROUGH REAL-TIME MONITORING.

Our cloudbased technology lets you manage your assets wherever you are, secure and live. Take control of the operating performance and profitability of your gas engine by giving it a digital life.

Gain a whole new level of insight into the performance of your industrial assets. myplant Performance – INNIO‘s Asset Performance Management (APM) solution – helps you increase your profits while decreasing the cost of your day-to-day operations.

YOUR POWER. YOUR DATA. IN YOUR HANDS.

Take a closer look at how our myplant Performance solution can support your operational profit drivers. They include:

Optimized performance

Increased engine uptime

Reduced operating costs

Gain better performance and avoid onsite service checks through predictive monitoring.

Increase availability, avoid trips and reduce maintenance costs with remote connection.

Drive down operating costs and save time with a consolidated, comprehensive dashboard view.

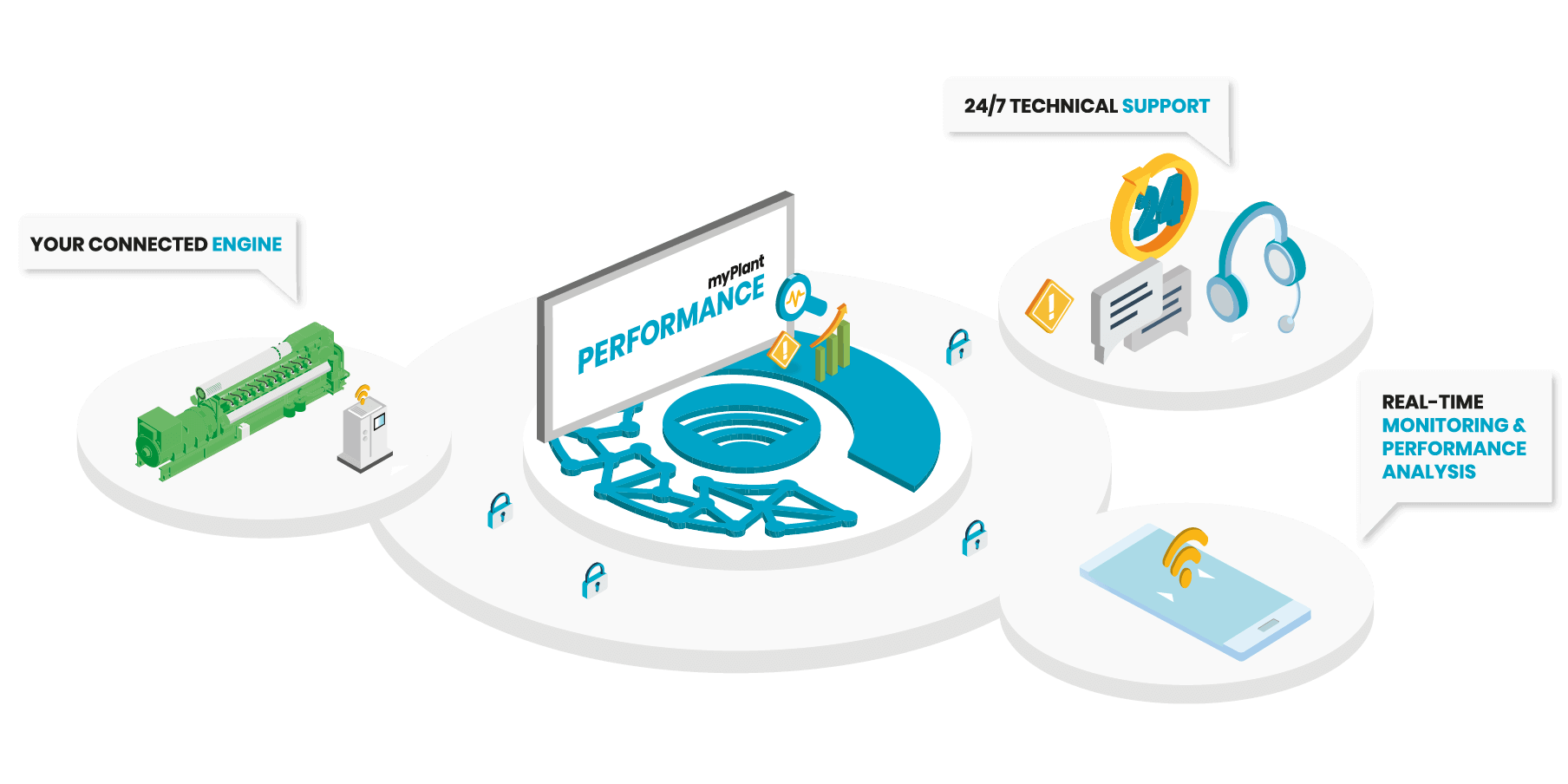

How does myplant Performance work?

YOUR CONNECTED ENGINE

24/7 TECHNICAL SUPPORT

REAL-TIME MONITORING & PERFORMANCE ANALYSIS

Digitization makes your plant fit for the future: and puts you in control of your engine’s performance.

We can solve more than 60% of your engine incidents remotely, reducing travel and maintenance costs and increasing uptime.

Use your preferred device to manage your engine in real time.

With us, you are always one step ahead: algorithms continuously evaluate your engine data, detect the smallest deviations at an early stage and can thus be solved

Why is security so important to us? Because it’s important to you.

Listen to Nikolaus Brunner, our Product Cybersecurity Leader, how we at INNIO embrace cybersecurity – so you can put your focus on your core business.

To use Youtube, please give your consent to the creation of cookies used by this service.

about myplant cybersecurity policies that keep your operations secure.

What our customers say

“With myplant Performance’s ability to continuously monitor our fleet’s health and solve more issues remotely, we are able to offer our customers a proactive, digitalized ‘value-centric’ service approach. Thus, they benefit from optimized maintenance, higher operating hours, and increased revenue.”

Tony Coleman, Northeast – Western Energy Systems, An INNIO Jenbacher Distributor

“The ability to monitor the engines’ key performance indicators is of utmost importance to us—both from a reliability and an efficiency standpoint. Our myplant Performance user apps and interfaces are very friendly to work with, and provide an instant overview of engine condition for maximum predictability.”

Jacco Besuijen, Energy Manager at Prominent, An INNIO Jenbacher Customer

Our myplant Performance solution gives you the right information at the right time for your entire industrial site or gas engine.

Explore myplant Performance’s powerful features and see how.

Comprehensive asset dashboard

- See your site’s operational and performance data during your selected period.

- View asset and component status, start success rate, operating hours, number of shutdowns, alarms, analytics, and more.

- Customize the dashboard for your specific needs by trending four different engine elements of your choice.

- No need to waste time searching: find the latest support cases and all relevant engine documents on the same dashboard!

Emissions monitoring

When it comes to regulations, it’s better to know than guess. That’s why we have developed a novel feature for emissions monitoring, where you can (1):

- Monitor your engine’s emissions levels during your selected period.

- Download an emissions report to simplify compliance with your country’s latest emissions regulations.

- Customize your own emissions notifications when combined with myplant Performance’s rule-based analytics.

(1) Emission upgrade required.

Impactful predictive analytics

Don’t guess: Know it before it happens. Let myplant Performance algorithms do their work and notify you so that you can take preventive action.

- myplant Performance algorithms continuously analyze the data streamed from your engines to detect any deviations that could cause unplanned events.

- Based on the data from thousands of engines, analytics algorithms distinguish patterns of healthy engine operations—and note when deviations occur.

- When relevant deviations are detected—and before any unplanned events have occurred— you are notified immediately via email or SMS and receive instructions on what to do.

- Analytics algorithms also provide accurate lifetime predictions for engine spark plugs, lubricants and filters—so you replace them only when necessary.

Key customized notifications

- Manage notifications from a centralized location

- Easily create new notifications.

- Choose from three different notification categories: engine status, rule-based or emissions.

- With engine status-based notifications, receive notifications based on engine analytics, start/stop and tripped status updates, for example.

- With rule-based notifications, customize your own metrics (for instance, when gas temperature decreases to x° C) and receive notifications on those metrics.

- For emissions notifications, learn when set emissions levels are exceeded.

Secure remote control

Access your engine—and resolve your event—remotely.

- Access and operate your engine as if you were standing in front of your engine controller.

- Adjust engine parameters according to your needs.

- Know that access to your engine controller is protected with multiple security measures.

Data trending

Plot historical data with a diagnostic workbench to quickly resolve engine events. Combine it with our secure remote connection for even better results.

- Simultaneously explore and compare data trends of multiple engines and data items.

- Choose your favorite engines and data items to optimize your workflow.

- Review data items against engine alarms to find correlations.

- Download graphs in multiple formats (JPG, CSV, XLS) and share your findings with your team.

Reporting and data consolidation

Get valuable fleet-level insights through myplant Performance’s automated reports.

- Get insights on fleet operations, connectivity, maintenance and performance to stay on top of key topics.

- Drive operational savings by automating your reporting processes.

- Integrate oil and coolant reports from your used laboratory to store all necessary data in myplant Performance.

3 choices to meet your needs

We listened … and created three different myplant Performance plans—so you can find just the right fit. Whether you need basic monitoring or highly advanced performance analysis and predictive analytics, we have the plan for you.

Starting up:

BASIC (FREE)

- Live operating status

- Alarm management only

- Access to all engine documents

- Mobile app

- Daily status logbook

Increased productivity / strong performance

- Recommended maintenance**

- Support case management**

- Spark plugs lifetime prediction only

- Engine emission monitoring only

Lower maintenance cost:

CARE

- Live operating status

- Alarm management and notification

- Access to all engine documents

- Mobile app

- Daily status logbook

- Historic and live data trending

- Remote access to engine controlleR

- Fleet management

- Engine status notifications (SMS/Email)

Increased productivity / strong performance

- Recommended maintenance**

- Support case management**

- Predictive maintenance for spark plugs, oil and filter

- Oil & coolant quality monitoring

- Fleet emission monitoring

Strong analytics:

PROFESSIONAL

- Live operating status

- Alarm management and notification

- Access to all engine documents

- Mobile app

- Daily status logbook

- Historic and live data trending

- Remote access to engine controlleR

- Fleet management

- Engine status notifications (SMS/Email)

Increased productivity / strong performance

- Recommended maintenance**

- Support case management**

- Predictive maintenance for spark plugs, oil and filter

- Oil & coolant quality monitoring

- Fleet emission monitoring

Artificial intelligence & predictive analytics

- Operator analytics package

- Historic performance analysis

- User-defined monitoring

- On demand: Access to myplant data via API (Application Programming Interface) service

**Recommended maintenance and support case management are only available to INNIO’s direct end customers with service agreement.

Rely on our many years of engine manufacturing experience and fleet operability knowledge with more than 18,000 connected assets:

30 billion+ minutes of connected assets

1.7 million+

monitored sensors

14 TB+ of data processed every year

70+ preventive analytics available

COMPLETE THE FORM TO GET STARTED WITH myplant TODAY

Our dedicated Jenbacher experts are available to provide personal consultation.