OTHER ENGINE TYPES

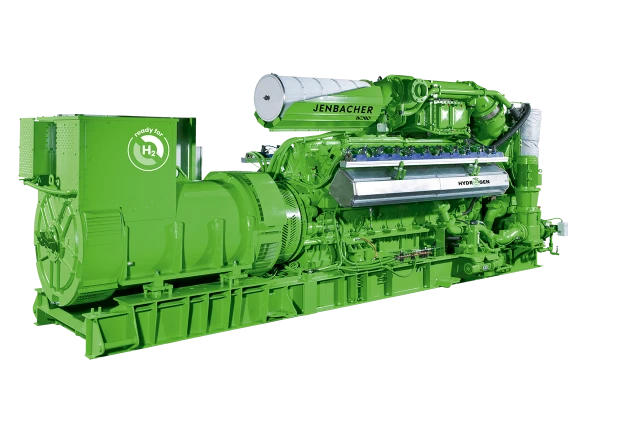

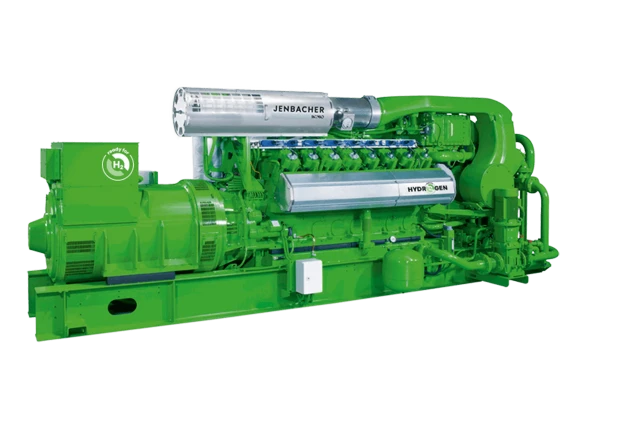

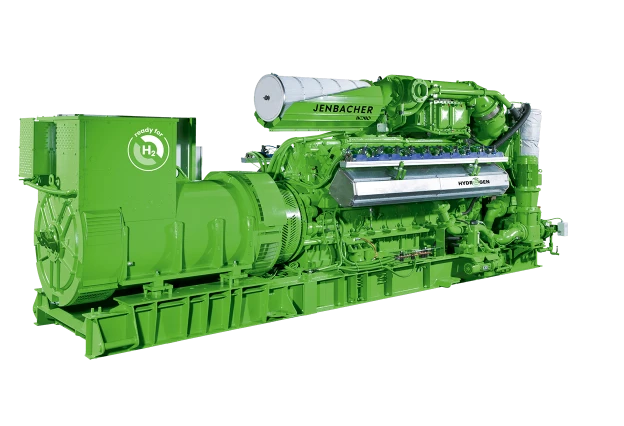

Jenbacher Type 4

Based on the proven design concepts of Jenbacher Type 3 and Type 6 engines, Type 4 gas engines are characterized by high power density and outstanding efficiency.

Enhanced control and monitoring provide easy maintenance capabilities, as well as excellent reliability and availability.

5,800+ engines delivered since 2002.

-

RESOURCES

Discover models:

Change the scope of supply by clicking on a thumbnail.

Scope of supply:

* Provided technical data is for information only. Data ranges are calculated considering various gas quality levels and ambient conditions (standard or hot/tropical conditions, etc.).

Jenbacher can change the technical data unilaterally. In the case of such change, we will update the data on our pages as soon as we can.

Please reach out to our experts to get help with engines selection, obtain the technical parameters for your gas composition.

Output and efficiency at generator terminals. Energy input is according to DIN ISO 3046 and DIN 6271, respectively, with a tolerance of + 5%.

All data according to full load and subject to technical development and modification.

Based on emission values of 250 and 500 mg/Nm3 NOx at 5% O2 at dry exhaust gas.

Base for biogas and sewage gas versions: 65% CH4 / 35% CO2.

Base for landfill gas version: 55% CH4 / 40% CO2 / Rest N2.

Discover models:

Highlights of Jenbacher Type 4 engines

Jenbacher Type 4 engines have the same design, emissions control, and waste gas-to-energy capabilities as their Type 2 and Type 3 counterparts, plus high power density and outstanding efficiency in their power range.

- The high-power turbocharger allows optimal operation at higher air intake temperature and altitude.

- A hour-valve cylinder heads features enhanced swirl and channel geometry using advanced calculation and simulation methods, resulting in optimal cooling and combustion conditions.

- The Type 4’s connecting rod reduces bearing wear and is easy to maintain.

Applicable gas types include: natural gas, associated petroleum gas (flare gas), propane, biogas, sewage gas, landfill gas, coal mine gas, other special gases (e.g. coke, wood, and pyrolysis gases).

Scope of supply:

Scope of supply, dedicated for applications, which require power generation only. If you are looking for simultaneous power and heat generation, please consider Combined Heat and Power Module (CHP Module) scope of supply.

Minimum scope of supply for genset:

- Engine and alternator installed on the frame

- Control panel

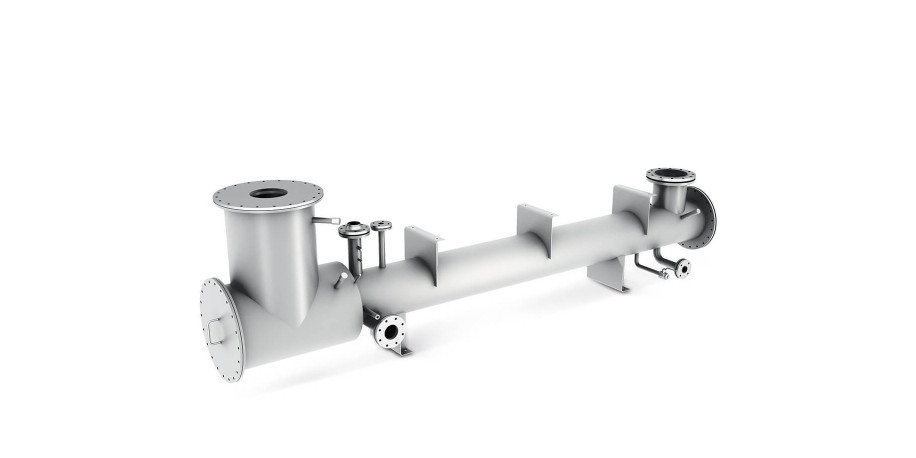

- Gas train

The scope of supply can be extended further with various balance of plant options (BOP), reach out to our specialists for help in selecting scope of supply and BOP options to fulfill your project’s needs.

Gensets can be installed inside a building or inside a container. To see more details about our containerized solutions, click here.

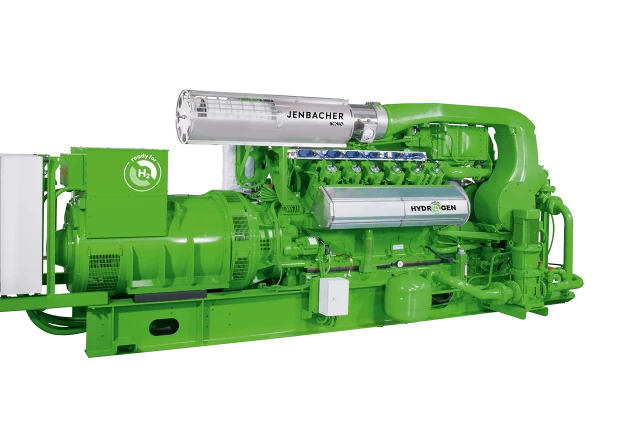

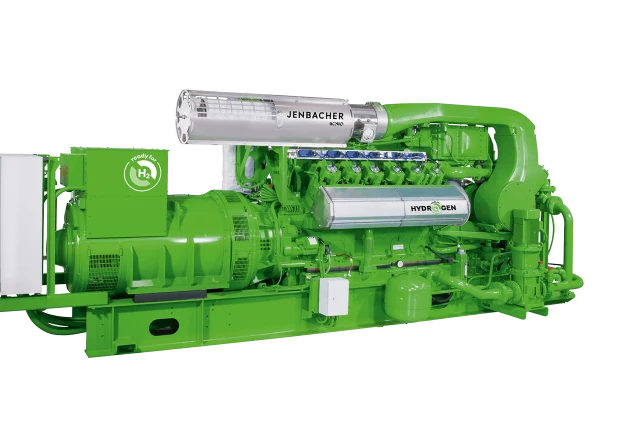

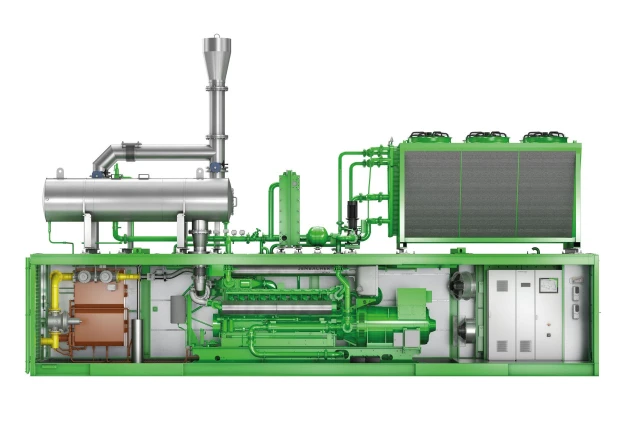

Combined Heat and Power Module (CHP Module) solutions allow customers to generate power and heat simultaneously at a very high total efficiencies, reaching 90% and even more.

Usual scope of supply:

- Engine and alternator installed on the frame

- Control panel, gas train

- Heat exchangers including exhaust gas heat exchanger

CHP Modules can generate hot water or steam at various parameters and can be integrated with your existing heat infrastructure. You can select the option that fits your project’s needs among the various heat recovery schemes provided by Jenbacher.

The scope of supply can be extended further with various balance of plant options (BOP), reach out to our specialists for help in selecting scope of supply and BOP options to fulfill your project’s needs.

CHP Modules can be installed inside a building or inside a container. To see more details about Jenbacher’s containerized solutions, click here.

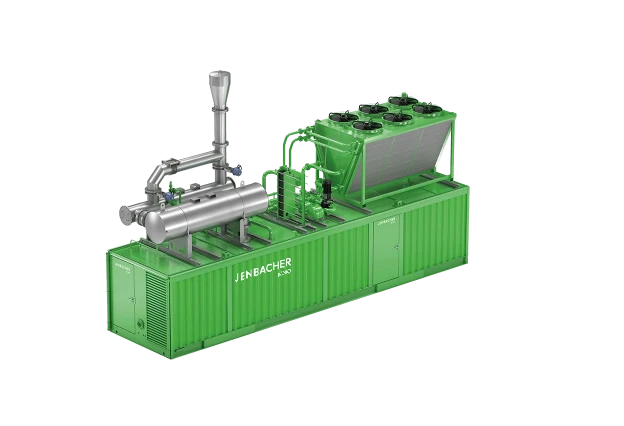

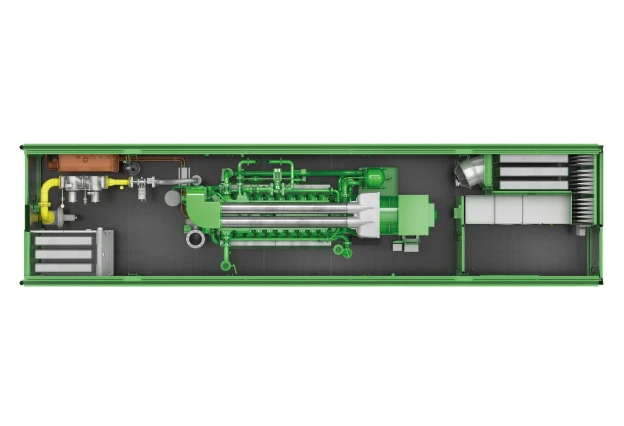

Jenbacher’s containerized solutions are “ready-to-use” power plants, allowing customers to minimize commissioning time. Jenbacher has produced containerized power plant solutions for decades, providing customers state of the art power generation technologies wrapped in well-designed, reliable packages.

Both genset and CHP module solutions can be supplied as containerized versions depending on your needs.

Usual scope of supply:

- Engine and alternator installed on the frame

- Control panel, gas train

- Container with integrated ventilation system

- Cooling systems

- Lube oil supply system

- Exhaust gas heat exchanger (for CHP module)

The scope of supply can be extended further with various balance of plant options (BOP), reach out to our specialists for help in selecting scope of supply and BOP options to fulfill your project’s needs.

Balance of Plant (BOP)

The right auxiliary equipment is of critical importance in ensuring that a power solution is economically feasible and provides your business with reliability, availability, and efficiency. Click on the provided BOP options to learn more.

Reach out to our experts to select the configuration that fits your business’ needs.

Available BOP elements may vary, depending on the engine and application type.

Proven Efficiency

Offering superior efficiency with an innovative engine concept, Type 4 engines save on fuel without sacrificing flexibility or reliability.

The flexibility to do more

The Type 4 is available in 50 and 60 Hz and features fuel and solution flexibility—making it an excellent choice for more than 10 different applications.

Reliability you can count on

With their reliability, dependability and high degree of availability, it’s easy to see why over 2,000 Type 4 engines have been delivered.

Type 4 Case studies

Hyosung (KOR)

with Asia Pacific’s first 100% hydrogen engine power plant

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

La Cira (COL)

for lower energy costs, greater reliability, and reduced emissions

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

Mavrorachi Landfill (GRC)

Sustainable HELECTOR project with Jenbacher engines in Greece wins global environmental award

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

Agrotor (HND)

uses waste byproduct for power generation

Location

Installed engines

Electrical output

Total efficiency

Energy source

Commissioned

Biotown (USA)

to power and heat from RNG/biomethane

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Den Berk Délice (BEL)

with combined heat and power

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Hyosung (KOR)

with Asia Pacific’s first 100% hydrogen engine power plant

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

La Cira (COL)

for lower energy costs, greater reliability, and reduced emissions

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

Mavrorachi Landfill (GRC)

Sustainable HELECTOR project with Jenbacher engines in Greece wins global environmental award

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

Agrotor (HND)

uses waste byproduct for power generation

Location

Installed engines

Electrical output

Total efficiency

Energy source

Commissioned

Biotown (USA)

to power and heat from RNG/biomethane

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Den Berk Délice (BEL)

with combined heat and power

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Our Services

Jenbacher Services

Bringing proven outcomes across the life cycle of your gas engines means less unplanned downtime, greater workforce efficiency, and lower operating costs. From commissioning to overhauling, our global network of qualified service experts provides the support you need, when you need it, by providing the latest technology.

Consult an expert

Send us a message and we’ll contact you to start the conversation.