Jenbacher Remanufacturing Program

Innovative solutions that give your engine and parts a new life

The Jenbacher Remanufacturing program gives your engine and all of its parts a new, longer life, returning used components to like-new conditions. When you buy a Jenbacher Remanufactured product, you get the same OEM quality and product reliability at a fraction of the cost of a new engine or part—all with a smaller environmental impact 1.

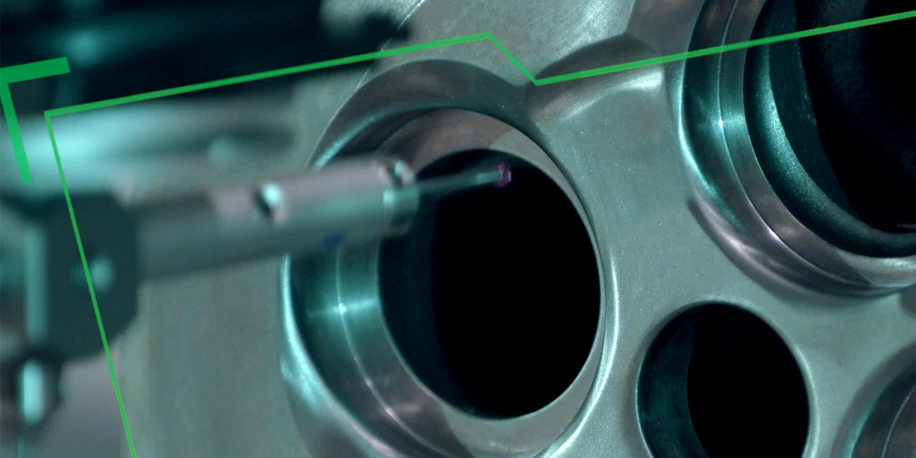

Our Remanufacturing Process

INNIO maintains a newly Remanufactured—not just rebuilt—attitude. In fact, INNIO’s Remanufacturing Program designs, engineers and delivers only genuine components that meet our exact standards and specifications.

With our holistic and systematic five-step Remanufacturing process, our engines and parts are carefully re-assembled and comprehensively tested before delivery. In this way, we help ensure that all parts work together in harmony for optimal system performance.

DISASSEMBLY

& CLEANING

Engines and parts are disassembled and cleaned by skilled personnel to eliminate and remove elements that can hide flaws.

PAINTING,

PACKING &

& SHIPPING

Engines and parts are painted or preserved and carefully packaged to ensure they are protected from the elements and can be installed right out of the box.

INSPECTION

All engines and parts are carefully inspected and thoroughly tested. We use OEM dimensions and tolerances to ensure specifications are met.

TESTING

Every engine and part that leaves the factory has been comprehensively checked.

Each test is recorded and stored electronically to maintain quality controls.

MACHINE

& ASSEMBLY

Skilled assemblers follow exact standards and specifications from the most current engineering drawings when remanufacturing parts. All worn parts that do not meet our strict requirements are replaced by new OEM parts.

Remanufacturing is the process of returning end-of-life products to the same condition as new ones. Sometimes, with the latest technology upgrades, we can even improve them!

This video explains the steps involved in our Jenbacher Remanufacturing process and provides you with insights into our advanced Remanufacturing world.

To use Youtube, please give your consent to the creation of cookies used by this service.

The basis of our Remanufacturing process is an exchange program in which you can receive our Remanufactured products before you give us your used components back.

Why Jenbacher Remanufacturing?

Our Remanufacturing strength:

17 Logistic & Remanufacturing Centers

10,000+ m2 dedicated Remanufacturing space in Jenbach, Austria

500 Jenbacher engines passing our Remanufacturing & Repair process annually

More than just Remanufacturing…

With our Remanufacturing program used engines and parts are returned to like-new condition and can provide you much more…

Uptime

More uptime means better production. And better production means higher profits. That’s why our OEM remanufactured products are not just rebuilt. They are carefully re-assembled and comprehensively tested before delivery.

Distribution

Select from a variety of convenient distribution options for fast and easy access to our remanufactured products. They are carefully packaged to ensure they are protected from the elements and can be installed right out of the box.

COST SAVINGS

QUALITY OEM CAPABILITY

RELIABILITY

ENVIRONMENTAL FOOTPRINT

OEM quality, product reliability, and long-term performance improvements are available at a fraction of the cost with our remanufactured products.

Protect your operational investment by relying on OEM materials, standards and specifications that deliver the same warranty as our new products.

Our holistic and systematic Remanufacturing process delivers high reliability by returning worn parts to original or the latest OEM specifications.

We save resources and reduce environmental impact by reusing materials, while helping increase efficiency, energy savings, and plant performance.

100% OEM components allow you to give your engine a digital life with myplant:

Listen to our long-term customer Martin Brinkmann, Director EnviTec Service GmbH, why he counts on our Remanufacturing Programs for servicing his Jenbacher gas engine fleet in Germany.

To use Youtube, please give your consent to the creation of cookies used by this service.

Our Remanufacturing program offerings

To meet your individual requirements, INNIO offers you a choice: Our Remanufacturing programs are available for your entire engine as well as for specific engine parts. We call our Remanufactured products—reUp engines and reUp spare parts.

reUp Engines

The engine is the heart of your plant installation, and efficient engine performance allows you to operate with confidence. With our reUp engines portfolio, we support you to give your engine a second life.

reUp Spare Parts

An engine is only as good as the parts inside it. And when your gas engine’s core parts are not in proper working order, engine efficiency declines. With our reUp spare parts portfolio, we support your successful plant operation.

1 Reducing your environmental footprint by reusing materials whenever possible

Our dedicated Jenbacher experts are available to provide personal consultation.